Introduction

The Digital Twin is considered one of the technology trends with the greatest growth potential. To get an idea, according to Markets and Markets Research its global market was calculated at 3.1 trillion (billions) in 2020 and some of the estimates from various consulting firms predict that the use of Digital Twins will exceed 115,000 billion in all industrial sectors, from improving energy efficiency to aerospace.

Many of us have heard of Digital Twins in recent times, butwhat does it mean? what is its origin? what are their advantages, features and applications? how can an organization define and create the requirements that define it? And what are your future challenges? These are some of the questions that I will try to answer in this article.

What is a Digital Twin?

We can find numerous references and definitions of this technological concept and, in all of them, we will find a common denominator: they will talk about a virtual representation of any physical asset (infrastructure, object, …) and/or real process. However, the 3D and virtual representation by itself is not a Digital Twin.

A Digital Twin can be defined as virtual representations of real-world entities (assets) and processes synchronized with each other at a specified frequency and fidelity. It gives us the opportunity to simulate scenarios and optimize our decisions using real-world data sets within the relative safety of virtual spaces. It is also a cornerstone in the famous and current metaverse (rapidly emerging virtual shared space that is already influencing the digital economy).

Digital Twins are recognized as an essential enabler of digital transformation. In addition, the COVID-19 pandemic has made us rethink many production, work and maintenance models and processes, and this has undoubtedly accelerated and boosted the adoption of digital technologies and solutions, including the Digital Twin.

The origin

Its first uses are found within the aerospace industry, although its concept was first referenced and related to the presentation of the PLM (Product Lifecycle Managenet) methodology in 2002 at the University of Michigan by Michael Grieves.

In 2010, NASA names the concept for the first time and starts talking specifically about “Digital Twin” in a draft technology roadmap.

Features and benefits

As we said before, the virtual representation from a 3D model is one of the features of a Digital Twin, but it is only a part of it. I believe that the cornerstone of every Twin is data. It is very important to use historical data, if available in the case of legacy systems, to feed it to the Twin, so that it can understand the behavior and be aware of past incidents. The use of sensor data from the actual asset or procedure is also essential.

The benefits of a well-built and well-fed Digital Twin are many:

- Increase the reliability, functionality and operational availability of the actual asset and/or process.

- Reduce operating risks

- Reduce maintenance costs

- Improved production

- Implementing optimal improvements or upgrades with greater agility

We achieve all of the above by running simulations on the Twin or by running behavior prediction algorithms on it, based on the data received.

Digital Twin applications: a case study

As we said at the beginning of this article, the Digital Twin can be applied in multiple industries, if we take as an application in the field of In the world of defense, we could, for example, design a Digital Twin that from the beginning of its conception would have as objectives to be achieved:

- Maintain high operational availability of systems and platforms. Using our Twin for the definition of failure predictions, predictive and prescriptive maintenance.

- Helping to provide a high autonomy of our systems and platforms to increasingly protracted conflicts. With our Digital Twin we could reduce delivery times, from the digitization of the logistics chain and supply chain to forecast, for example, how many spare parts are actually needed and predict when they will have to be shipped based on the actual context situation.

- Increase resilience by, for example, implementing technology upgrades with guarantees and previously simulated in different scenarios, or by performing a proactive obsolescence cure.

As we can see, a Digital Twin for sustaining and supporting the life cycle of systems and platforms is undoubtedly one of its main applications.

What future challenges does this technology face?

One of the current challenges we face in organizations in the definition and development of a Digital Twin is the lack of standards in terms of models and architectures. I am only aware of one regulated and standardized framework for the development of Digital Twins, only applied to the industrial manufacturing sector, published by the International Organization for Standardization in its technical standard ISO 23247. There are also associations, such as the Digital Twin Consortium, that seek to promote the knowledge, adoption, interoperability and development of Digital Twin technology and, therefore, the definition of rules or standards.

Other difficulties and challenges to overcome for the establishment of technological maturity in the design and development of Digital Twins are:

- It is still a novel technology with few practical and real use cases and success stories;

- As with any new technology, it is therefore associated with a higher cost and time investment for its development;

- As critical and relevant data of the actual asset and process status and its context is handled, this brings associated issues of security, privacy, data protection laws, etc..;

- Finally, we must also think that the Digital Twins will have their own life cycle and maintenance and upgrade requirementsThe assets, in many cases linked to assets with half-lives of a decade or more, may also be integrated into their own Digital Twin network where they exchange data and models.

How to create and define the requirements of a Digital Twin?

Having reached this point, we have already seen the meaning, advantages and convenience of its use, but when an organization decides or approves to create a Digital Twin it is easy to suffer from temporary paralysis when considering, but how do I start?

I always like to answer a simple questionnaire before starting to define a project.Why do I need it, do I want it to improve the life cycle support of a legacy platform, do I need it to improve my engineering and manufacturing designs? Being clear about the objective to be achieved and the functions I will want to perform with the Digital Twin is of paramount importance.

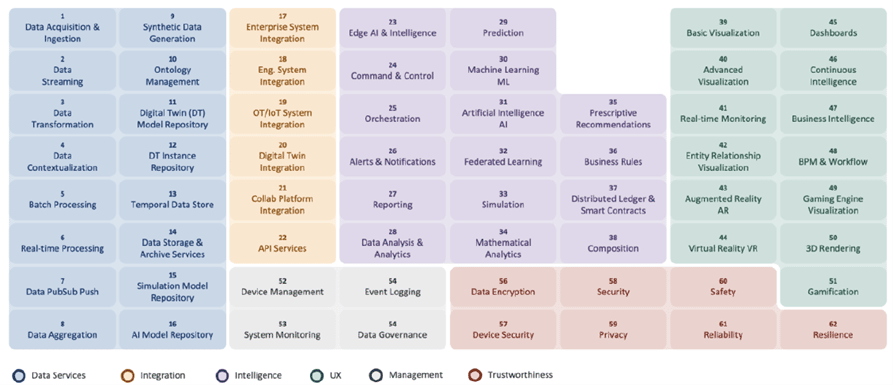

Other questions to ask are: why, is it necessary, is it really going to bring me benefits or am I falling victim to the adoption of a technological fad? Once these questions have been answered honestly and clearly, the next step is to define the requirements to be met by my Digital Twin and, for this purpose, I find particularly practical the Periodic Table of Digital Twin Capabilities created by the Digital Twin Consortium

Digital Twin Consortium

as a user guide:

Figure 1. The Digital Twin Capabilies Periodic Table

The periodic table of Digital Twin Capabilities (CPT) is an architecture and technology independent requirements definition framework. It is aimed at organizations that wish to design, develop, implement and operate Digital Twins, provides an easy framework to describe the key capabilities required and a good starting point in defining and creating our Digital Twins.

Pablo Segovia, KAM Defense Sector at Tecnobit – Grupo Oesía