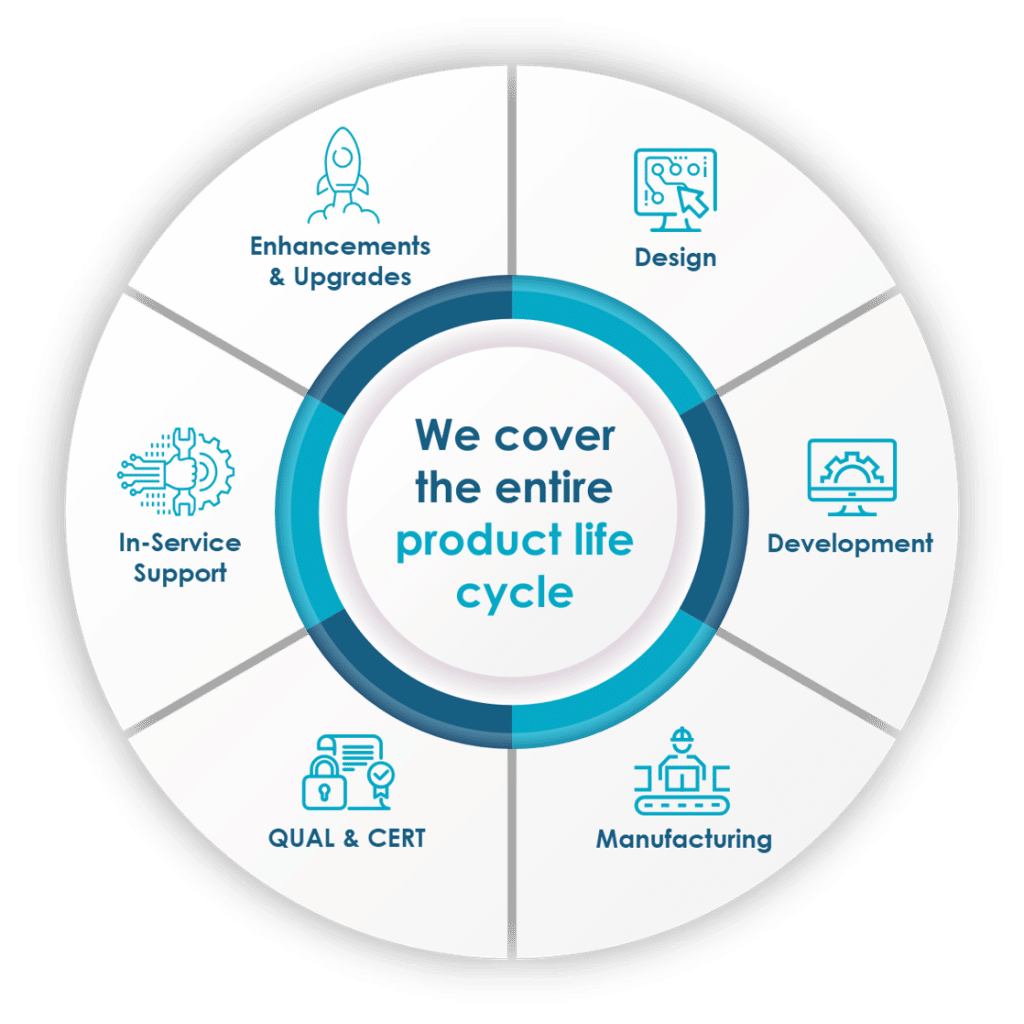

Life Cycle

We guarantee that our systems are operational and available at any time and place.

We cover the complete life cycle of our high-tech products and systems, from design, development, manufacturing and certification to maintenance.

We are committed to be your most reliable supplier, always at your service.

Design

Our continuous innovation allows us to develop new high-tech product ranges to provide a fast and efficient response to all markets.

We have implemented work processes that ensure the highest level of excellence in all areas of design, sw/hw engineering, mechanical and electronic design, under the strictest quality standards.

Development

We have highly qualified engineers that integrate multidisciplinary teams covering all stages of the life cycle, from the creation of requirements to the Verification and Validation (V&V) of the products we manufacture.

Systems Engineering

HW/FW Engineering

SW Engineering

ILS Engineering

Manufacturing

We are committed to quality and innovation, that is why we offer you a high technology production center that works with the highest levels of exigency.

Our staff is highly qualified, technicians and quality inspectors are IPC (CIS) certified specialists and manufacturing engineers who support production IPC (CIT) certified trainer.

Qualification and Certification

We offer our customers robust and reliable solutions because we are fully committed to delivering high quality products.

We have the capabilities to carry out climatic, temperature, humidity, vibration, shock, or thermal tests, and we have developed a complex protocol for specific test control and testing.

Following this commitment, we have achieved the highest quality standards.

Service Support

We offer you our experience of more than 45 years providing intelligent support to the life cycle of our own and third party products.

Our extensive experience and capabilities allow us to offer a tailor-made service model that starts in the early planning stages and continues throughout the life of the systems, up to their final decommissioning.

We provide different services adaptable to your specific needs, ensuring the maximum operational availability of the equipment.

Our Sustainability Model includes 3 main phases:

Support Approach

We designed a support service that optimize product life cycle cost with optimal installation and start-up solutions, as well as installation and commissioning solutions, as well as spare parts management and supply.

Service Support

We provide MRO (Maintenance, Repair and Overhaul) services for our own and third party systems, offering reduced TATs (Turn around time) thanks to the experience of our workforce, the spare parts policy implemented and the complete availability of our technical support team.

Our Technical and Operational Support guarantees service delivery, improves the performance of your installations and integrates seamlessly with your operations.

- We cover the different types of maintenance services:

- Maintenance Level “O” (Operational)

- Maintenance Level “I” (Intermediate)

- Maintenance Level “D” (Depot).

- We extend the useful life of your equipment by performing obsolescence cures and we keep the systems updated at all times.

- We use artificial intelligence techniques applied to prescriptive maintenance to manage the management and monitoring of systems.

- We analyze the maintenance and creation of models capable of predicting recommendations, implemented machine learning models capable of prescribing maintenance recommendations.

End of Support

We provide intelligent and cost-effective solutions to facilitate the sustainability of the affected system,

- On-site support team

- Information solutions

- Engineering and logistics management

- Supply chain logistics

- Operations and maintenance follow-up

- Environmental compliance

Upgrades and Modernizations

We offer tools that help you make decisions about the future use of equipment, with assessments that determine the current and future condition of equipment in order to schedule upgrades and modernizations that extend equipment life.

We offer

scalable support

at three levels

Basic

We support activities where you have primary responsibility and control over maintenance and logistics.

Extended

Through annual or multi-year maintenance contracts, we manage customized support at your facilities.

Integral

We provide a turnkey solution that covers the entire life cycle of your systems.

Our greatest pride, the trust of our customers

Who trusts us

Do you need more information

of our services

for your organization?

Contact our specialists and they will advise you on what is best for your organization.

Phone

+34 91 309 86 00